What is RFID technology and how does it benefit growers? In today's blog post we'll take a look into this valuable tool that's helping transform horticulture.

What is RFID?

Radio-Frequency Identification (RFID) is the use of radio waves to read and capture information stored on a label (or tag) attached to an object, such as a pallet or bin. You may encounter several RFID systems every day - they are present in stores as a theft prevention measure, office buildings as a gatekeeping tool, and perhaps even your own car if you have a transponder for toll roads like Ontario's 407 highway.

How Does RFID Work?

An RFID system is composed of tags and a reader. Within every RFID label is a microchip that stores and processes information, along with a tiny transmitter and a receiver. The label contains the specific serial number for one specific object.

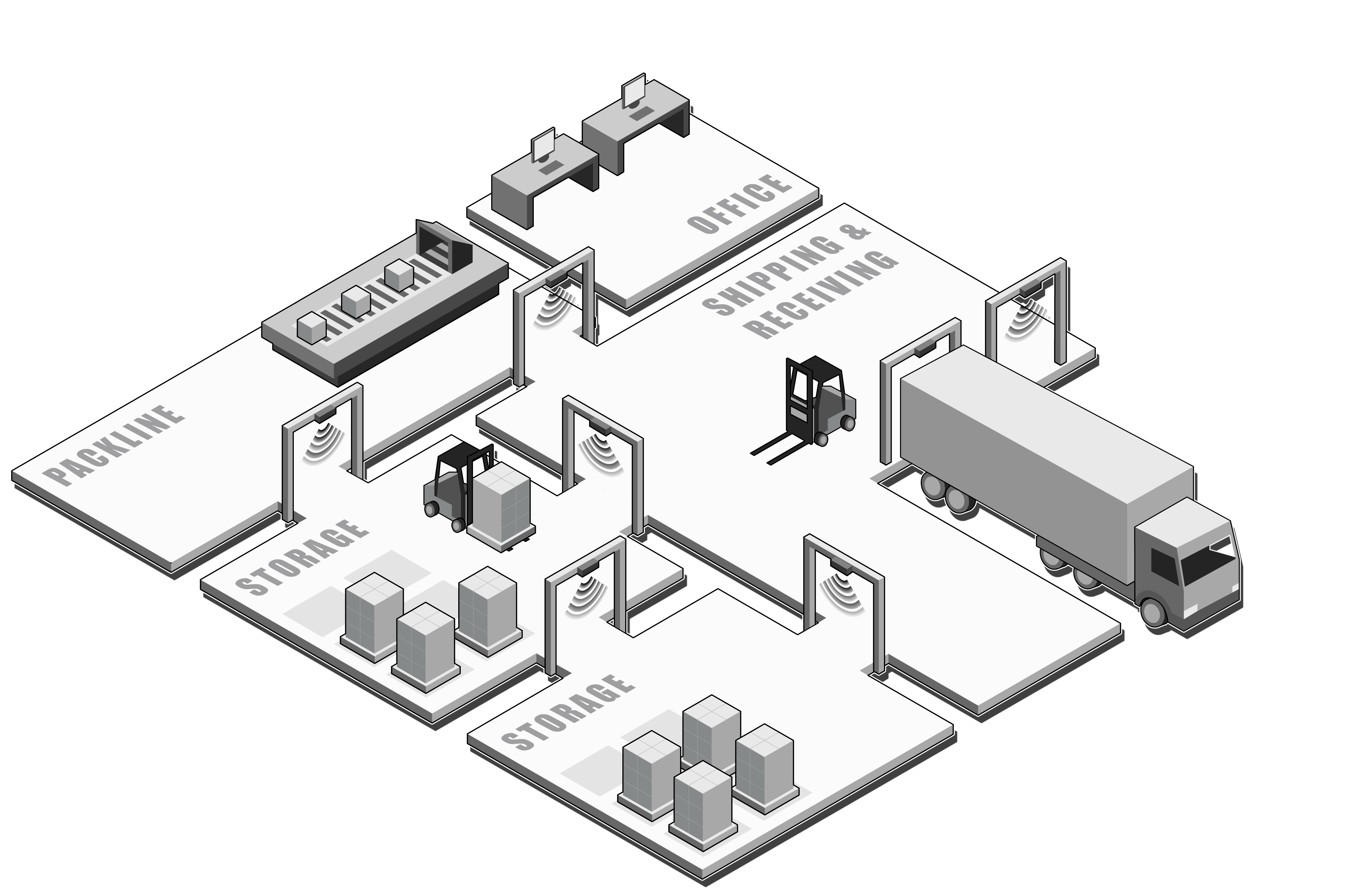

To read the information stored in a label, the RFID reader emits a signal to the tag using an antenna. The tag responds to this "call" with the information written in its memory bank. The reader will then transmit this information to a compatible software program - such as Croptracker. The result is lightning-quick, automated inventory management.

How Is It Different From Barcoding?

You're probably noting the similarities between RFID and barcoding systems - however, there are significant differences. Unlike a barcode, an RFID label can be read in-motion, from up to several feet away, and are not obstructed if covered in mud and dirt. RFID labels can also hold up to 2KB of data, whereas a barcode only represents 10-12 digits. Finally, a single RFID tag can be reprogrammed over and over again to flexibly represent new items and hold new data - meanwhile, a barcode can only represent one set of information in its lifetime.

What Are The Benefits of RFID To Growers?

Croptracker introduced the RFID components of our software in 2015. Since then, it's been easy to see how RFID technology advances our mission of helping make crop production more profitable, efficient, and safe.

Lowered costs through automation - Croptracker users who tag pallets or bins with RFID and install RFID readers in their packing facilities' entryways eliminate time and labour costs spent manually adjusting inventory as pallets enter and exit the packhouses. This automation has allowed some users to significantly expand their packing facilities.

Improved production throughput - RFID readers record incoming and outgoing palettes almost instantaneously, allowing for faster packing and order processing. Click this link to see the pace at which RFID readers and the Croptracker software work together.

Reduced errors - RFID readers are not suspectible to the risk of human error, reducing costly mistakes.

Enhanced traceability - By affixing RFID labels to pallets sent out into the field/orchard, participating Croptracker users are able to trace these same pallets later back to the exact block.

Swift recall management - When a problem is found with a palette, Croptracker users can easily identify and investigate the originating block, and hold back and inspect other palettes from the same block.

Interested In Implementing RFID In Your Operation?

Talk to us about how we can get RFID technology working for you. From hardware sourcing to set-up to comprehensive training, we're excited to help your operation realize the time- and money-saving and traceability-boosting benefits of RFID.