Welcome to the first part of our series on precision crop load management. Over the next few weeks, we will be taking a close look at methods and models of precision crop load management in orchards. Crop load management is a vast topic, so this week we’re starting with some of the key concepts and terms and introducing the three main methods: Pruning, Chemical Thinning, and Hand Thinning.

What is Crop Load Management?

The process of pruning and thinning buds and branches before harvest to maximize fruit quality and yield, more commonly referred to under the umbrella term “crop load management” has attracted a lot of attention over the last ten years. This is due in part to the popularity of the Honeycrisp apple. Ranking in the top five most popular apple varieties in the United States throughout the 2010s, Honeycrisps are a sensitive fruit, with highly specific requirements for growing, harvesting, and even storing. The need to maximize yield and quality of this extremely finicky variety is even greater due to the high cost of production, but quantity doesn’t always equal quality. Trees that are forced to overproduce due to under-thinning will produce fruit of a lower quality, and may even push the tree into a biennial bearing pattern; an apple farmer’s worst nightmare where a tree produces too much fruit in an “on” year and then too little or none at all in a subsequent “off” year.

Crop load management is one of the most difficult aspects of growing, but it has a huge impact on the value and profitability of orchards every year. Some experts suggest that proper crop load management can add anywhere from $5000 to $10000 per acre at harvest time. Obviously, the potential for return is high, but the complexities of precision pruning and thinning mean that many growers just don’t have the tools to analyze their historical data, let alone the detailed day-to-day weather and growth tracking required for precision thinning models.

Crop load management has three main aspects: Pruning, Chemical Thinning, and Hand Thinning. In the simplest terms, crop load management is about creating the ideal ratio of fruit to branch (or fruit to tree in some cases) to maximize fruit yield and quality. It is in many ways an energy balancing act - and it can be a delicate operation to increase fruit quality without compromising the yield.

Pruning vs Thinning

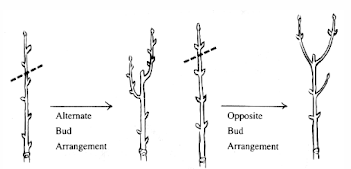

So what’s the difference between pruning and thinning? In layman's terms, the two are often used interchangeably, but technically pruning, chemical thinning, and hand thinning all fall under the “types of thinning” definition. In practice, pruning refers to small vertical or diagonal cuts made to a tree or woody shrub to shape the tree and maximize the growth of preferred buds.

When pruning in the orchard, there are two types of buds that growers will try to distinguish between: vegetative or leaf buds, and flowering or fruit buds. As the name suggests, vegetative buds will mature into foliage, while flower buds will bloom, flower, and produce fruit.

Bud counting, when a grower tries to estimate the number of buds per area, is usually measured in buds per branch or square foot. Recall the fruit-to-leaf ratio we mentioned earlier. Bud counting is a critical, if monotonous, aspect of calculating crop load. The ideal ratio of flower-to-leaf buds is one that has enough leaves to support the best quality fruit growth, and enough fruit to maximize profitability. Pruning can also be used to create branch patterns that will support and produce fruit in future seasons.

Thinning typically refers to the process of pulling out or removing entire seedlings or shoots to provide growing room for the remainder. It is particularly important in seeded plants like lettuce or radishes which are seeded closer together to guarantee more sprouts. In orchard terms, thinning has the same purpose: to ensure that buds on the tree will have enough space to grow into fruit of a reasonable size.

Thinning is a critical component of crop load management, and if done incorrectly it can have long-lasting effects on the yield and quality of fruit in the coming years. To help growers make better thinning decisions, a data-driven approach is necessary. This is where growth models can come into play. In brief, the two main growth models are the Pollen Tube Growth model and the Carbohydrate model. Both growth models can be used to support decision-making in the orchard, so stay tuned for the next blog in our series where we will go over these models in more detail!

Practical Methods

Now that we have established some definitions, it is time to dig into the three main methods: Pruning, Chemical Thinning, and Hand thinning.

Pruning

Pruning usually occurs early in the year when the trees are still dormant, between late fall when the leaves begin to fall, and early spring when the buds swell. Because it is very difficult in the early stages to reliably identify a fruiting bud from a leaf one (without cutting it open anyway) many growers will try to delay pruning as long as possible until buds are opening.

Pruning not only shapes the tree, but it also stimulates growth by keeping the tree-to-root system ratio balanced. A more robust root system compared to a smaller above-ground tree means more water and nutrients coming up from the roots for each remaining bud. More water and nutrients means more growth, a stronger tree, and ideally, high-quality fruit from the buds still left on the tree.

Chemical thinning

Chemical thinning is significantly less labor-intensive than pruning. In chemical thinning, a chemical solution, usually a type of corrosive or desiccant, is applied to apple or pear trees in the first month of bloom. Chemical thinning may inhibit the fertilization of flowers, or even pause photosynthesis. As discussed, too many fruits on the tree will cause fruit quality and size to decrease.

Forcing a tree to produce too much fruit in a given year is called “overcropping”. In overcropping, the tree spreads its energy resources too thin, causing it to produce fewer flowering buds next year. In sensitive varieties, overcropping can even push a tree into a biennial bearing pattern, like the Honeycrisp example we discussed earlier.

Hand thinning

By far the most labor-intensive, hand thinning usually occurs in June after petal fall; in apples and pears, hand thinning happens after chemical thinning. There are no chemicals currently approved in Canada for thinning tender fruit like peaches, so hand thinning is the only method available.

Hand thinning can also happen all throughout the season and is required more if the first two steps have not been done effectively. Fruit may need to be taken off later in the season if not enough blossom or bud was removed, or if chemical thinning was insufficient or ineffective. For organic growers who cannot rely on chemical thinning, more hand thinning of both blossom and fruitlet is required throughout the season. Hand thinning serves the same goals as chemical thinning; to create enough space for buds to mature into quality fruit.

Hand thinning is extremely precise work, and many growers struggle with how to instruct their workers to thin effectively. To help workers in the field with hand thinning decisions, tools that take into account the size of branches, the circumference of the trunk, and the space between individual fruits can be used. We’ll talk about the three most popular in-orchard tools, the equilifruit disc, the young apple thinning gauge, and the “rule of thumb” in part three of our precision crop load series, so stay tuned!

This week we just scratched the surface of precision crop load management. A complex process, if done correctly crop load management can have huge rewards at harvest time. On the other hand, poor crop load management in the orchard can have lasting effects on the yield of a tree for years to come. Next time, we’ll take a close look at growth models, and some of the latest research that growers use to support their decisions when pruning and thinning in the orchard. Check out part two of our series on precision crop load management here.

Interested in learning more about Croptracker? Learn more about our Farm Management Software, or book a demonstration to schedule a meeting with our product experts. Or if you liked this article, subscribe to our newsletter!

And as always, if you're ever stuck, never hesitate to e-mail us at support@croptracker.com or Live Chat with us by clicking the green speech bubble ![]() in your bottom right-hand corner. We're always happy to help, so Croptracker can make your farm more efficient, safer, and more profitable!

in your bottom right-hand corner. We're always happy to help, so Croptracker can make your farm more efficient, safer, and more profitable!