Controlled atmosphere (CA) storage as it is currently known and utilized is a 20th century innovation, but the fundamentals of how it functions stem from research conducted as early as the early 1800s. Best suited for fruits and vegetables that are climacteric – referring to produce that suitably ripens after being picked due to its emission of ethylene gas – CA storage greatly extends the freshness of a season’s harvest. Maximizing sales and limiting spoilage, CA storage practices enable growers to best participate in global supply chain markets. How can refined post-harvest insights further boost the benefits of investing in high cost storage infrastructure?

How does Controlled Atmosphere increase the lifespan of fruit?

Jacques Etienne Berard studied the concept of controlled atmosphere storage in the early 1800s in France, drawing the significant conclusion that fruits don't ripen when the local environment is depleted of oxygen. CA technology improved after the 1950s and became more viable for widespread commercial adoption during the 1990s, when major technical innovations justified use within international food supply chain systems. The high cost to adopt and maintain CA storage naturally zeroes in on what produce will best last in long-term storage, such as apples, kiwifruit, and pears. Apples in particular benefit from CA storage, in spite of potential aggravation or induction of storage disorders and diseases that must be accounted for.

Three key variables in creating an effective controlled atmosphere storage solution include precise management of temperature, relative humidity, and ethylene.

Temperature

Lowering the temperature of the area where fruits and vegetables are stored slows down respiration rates, as well as metabolic or degradation reactions. Though refrigeration is an integral tool for safely extending the life of food for consumption, not every fruit and vegetable responds favorably to cool temperatures. Cold stress, or ‘chilling injury’, presents itself particularly in tropical and sub-tropical fruits at temperatures below 12-13 C, and can include membrane breakdown that releases metabolites like amino acids, sugars, and mineral salts. Enzymatic reactions can occur from cells’ release of enzymes, which sets the stage for harmful microorganisms to cultivate.

The severity of chilling injury depends on duration of exposure and how low the temperature is – and it doesn’t have to be freezing to occur.

Chilling injury symptoms include:

- Surface pitting

- Discoloration

- Internal breakdown

- Flesh browning

- Failure to ripen

- Loss of flavor

- Decay

CA storage, over cold storage on its own, enables some side-stepping of the negative repercussions that can arise from low temperatures without other interventions. CA storage temperatures are typically kept between 1 and 3 degrees Celsius, though it depends on what is being stored. Modifying the atmosphere to feature low oxygen and high carbon dioxide reduces chilling injury rates in commodities like apples and pears, which are friendly to long-term storage.

Relative humidity (RH)

The relative humidity (RH) of a CA room is typically kept high, which assists in delaying ripening and limits chilling injury symptoms where relevant. Maintaining a humidity close to the saturation point (typically around 95%) prevents transpiration; this refers to the loss of moisture from living tissues that causes shrinkage and a deterioration of color, texture, flavor, and nutritional quality. Water loss of a stored product is also determined by temperature and air velocity of the storage room, as well its variety and maturity level.

Ethylene

A natural gaseous plant hormone, ethylene is released by fresh produce, boosting the respiratory activity and therefore, the ripening of fruits and vegetables particularly after being picked. Respiration activity alters physical and chemical characteristics like appearance, texture, taste, and color, as well as it is the key to produce aging into decay. Controlling ethylene gas production during the storage of climacteric fruits in particular enables long-term storage practices, through a suppression of the natural maturation timeline.

How is ethylene production artificially managed? Low temperatures, low oxygen, and elevated carbon dioxide conditions inhibit the activity of ACC synthase and ACC oxidase enzymes, and so the ethylene-release rate of commodities in CA storage can be slowed nearly to a halt, until it’s the desired time to let the natural process loose.

Managing chemical applications with Croptracker

Whether applied on the tree or as a post-harvest treatment, maintaining careful spray and chemical inventory records are important for adhering to regional legal requirements, as well as ensuring a safe work environment for work crews. Croptracker’s Spray module offers easy management of the important chemical data involved in your operation.

Executing the correct recipe for a spray application is simplified with Croptracker’s tank mix calculator. By building a recipe with chemicals already listed in the database (or adding one specific to your operation), an accurate recipe is automatically calculated for a spray plan. The calculator function assists with decisions like number of tanks required for a particular size of application, per block chemical amounts, and total chemical use. Chemical inventory tracking is automatically adjusted when applications are completed. Need to gather your data for a GAP audit report? Easily comply with regulatory requirements with centralized records.

Prepping fruit for Controlled Atmosphere storage

Chemical applications administered before fruit is sealed in CA storage further improve the benefits of the practice, by equipping growers and packers with another angle for controlling ethylene production. Agrofresh’s SmartFresh treatments contain 1-Methylcyclopropene. This controls the natural ethylene response early so “fruit matures on your schedule”, meaning it expands the harvest window so fruit can stay on the tree for longer. This leads to better results on color, size, and firmness – all in line with what customers demand. On top of the more aesthetic side of quality, Agrofresh has found that SmartFresh applications preserve the nutritional composition of stored fruit. Several studies have proven that SmartFresh technology contributes to slowing the decrease of Vitamin C throughout the whole apple supply chain, particularly if used during ultra low oxygen CA storage.

Ripelocker containers enable micro CA spaces in existing cold supply chain

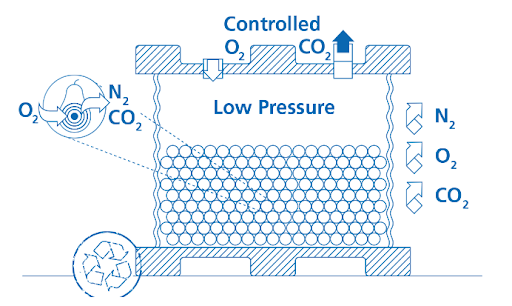

RipeLocker containers manage the atmospheric pressure, humidity and gas composition (oxygen and CO2) within the vessel to extend the life of fresh produce and flowers. Suppressing pathogen growth, considerably less decay will occur during storage – and RipeLocker containers can also provide the vehicle for delivering organic fungicide vapors to kill the pathogen. After successful efficacy trials, RipeLocker is now courting interested buyers across the US

Based on the specific needs of each type of fresh produce or flower, RipeLocker tailors operating parameters, such as internal pressure, oxygen and CO2 levels to optimize the longevity and freshness. The system responds to changes in the storage or shipping environment, making automatic precise adjustments to prevent damage and reduce decay.

George Lobisser, founder and CEO of RipeLocker, emphasized in September 2021 that the next phase of the CA container product innovation is market expansion. “Blueberries, cherries and flowers are just the beginning. The power of RipeLocker containers to fundamentally transform how growers and packers store and ship their produce is immense. In addition to reducing food waste, our product benefits the consumer by extending the fresh season as well as delivering a better eating experience.”

Creating the right conditions in a CA room

The carefully maintained environment of a CA storage room aims to keep ideal environmental conditions as uniform as possible. To generate a typical, fruit-friendly controlled atmosphere, operators will remove oxygen, remove excess carbon dioxide, introduce new air to replace oxygen consumed by respiration, remove ethylene, and sometimes reintroduce carbon dioxide. The nuances of how each level is executed will vary from variety to variety, but the fundamentals remain the same.

Types of structures for CAs

Similar premise but through a different execution – postharvest controlled atmosphere techniques can vary based on available resources and what commodity you’re trying to preserve. Some prominent methods include:

- Controlled ventilation: This is the most basic type of CA. Generated through an accumulation of carbon dioxide from produce stored in an airtight space, C02 levels are adjusted with the introduction of outside air to create the sum of oxygen and carbon dioxide concentrations of atmospheres equal to 20-21%.

- Conventional: An airtight room with scrubbers for removal of excessive CO2 from the storage atmosphere (typically using lime or activated charcoal). Conventional CA requires appropriate measuring systems, a gastight room, and accurate remote temperature control.

- Low O2 Storage and Ultralow O2 Storage: Suitable for commodities that respond to a more pronounced deprivation of oxygen, this approach can improve quality without detrimental effects. Gas concentrations must be frequently adjusted to maintain the appropriate concentration.

Other methods include rapid CA, initial low oxygen stress, delayed CA, low ethylene, dynamic control, seal plastic tents, hypobaric/hyperbaric storage

Knowing when is best to break the CA seal

When planning the usage of space in the CA storage rooms for the season, additional insights gained by tools like Harvest Quality Vision can refine the way you best orchestrate tackling this year’s crop. When asking Landseer Limited’s managing director Mark Tully about the decision -making involved with packing CA store rooms in the best way, he explained that growers fill stores based on orchards relaying the general quality parameters of the season. This helps to determine the length of time fruit is in storage, and the particular CA parameters they are stored under.

Ideally, a room is filled with fruit from a single orchard before sealing the room. This doesn’t have to happen all in one shift, said Mark, but filling storage rooms is time sensitive when the aim is to avoid ethylene production causing detrimental effects on the fruit. With a race against that natural process, sometimes rooms need to be filled with similar profile fruit from different orchards. “Stores should ideally be filled within two to three days, and certainly within seven days of picking.”

So when is the right time to disrupt CA storage rooms, after so much effort has gone into putting fruit into a freshness suspension? “Store opening is determined by two critical decisions,” said Mark. “First there is, ‘Does the fruit in this room meet a buyer’s quality expectations in terms of pressure, soluble sugar, and color specifications?’ The second question is, ‘Will the contents of this room meet the size profile that is sought by customer orders?’ Having this information documented in detail, prior to sealing a room, enables a more conscientious choice to open the room at a later date without a high risk of error. Fewer mistakes at this point in the supply chain optimizes inventory for better sales outcomes and limits undue loss.”

To have the most comprehensive insight into an order without painstakingly assessing a lot, Mark recommends Croptracker´s Harvest Quality Vision system, explaining that prior to its arrival on the market, “the only way of achieving [comparable insights] has been pre-grading, or really intensive sample sizing prior to filling store rooms.”

Streamline receiving and storage planning with HQV

Presorting is typically energy intensive, but it’s well worth the trouble when fruit is going to be stored for when the best suited buyer is ready to have their order fulfilled, or shipped out as soon as possible. Pack-to-order invites opportunity for cost savings through better storage use – with fewer mispacks and a higher rate of quality among pieces stored, there’s less need for space to accommodate loose pallets that are in need of a buyer

Since packed pallets can’t be stacked, being stuck with some that aren’t able to ship yet is a drain on space resources. Repacking increases the rate of damaged pieces, so full pallets tend to stay put once assembled. Ship the ideal fruit for its next supply chain destination with quick turnaround and little handling with a “virtual presorting” tool like Harvest Quality Vision, and enable a strong pack-to-order inventory strategy by knowing the size and color distribution of the lot. Capturing the details with a quick scan eases the pressure of making the right storage decisions – the size and color distribution breakdown speaks for itself.

Croptracker develops agtech solutions for industry leaders. Our mission is to make crop production safer, more efficient, and more profitable. Designed with fresh market producers and distributors in mind, every tool we create is based on direct industry feedback. Croptracker’s award-winning farm software optimizes recordkeeping, labor tracking, production and cost management. Our integrative Harvest Quality Vision technology offers instant empirical analysis of crop samples exactly when you need it. Optimize your harvest season with Croptracker’s customizable solutions.