Improving the safety, efficiency and traceability of crop production is a central priority for Croptracker when considering the farm management ERP. Offering robust recordkeeping for all aspects of production and harvest, Spray is a key module that ticks off all the boxes for optimizing your operation, for the betterment of your crew.

Croptracker's Spray module is available in English and Spanish. Here are three ways that Croptracker’s Spray module can improve upon typical farm practices:

Make optimal decisions at the best time

Farm managers must assess the perceived best course of action on using resources throughout production. Tracking chemical inventory, cost, and usage with Croptracker helps answer the question 'Is the amount that could be spent on a spray application worth circumventing the potential loss of crops from pests or disease?’ Determine whether a spray application is the best use of resources with easy inventory management within Spray Events. Maintain an up-to-date inventory of your chemicals automatically, and analyze chemical usage and costs over time by identifying patterns from past usage.

Integrate safety equipment tracking

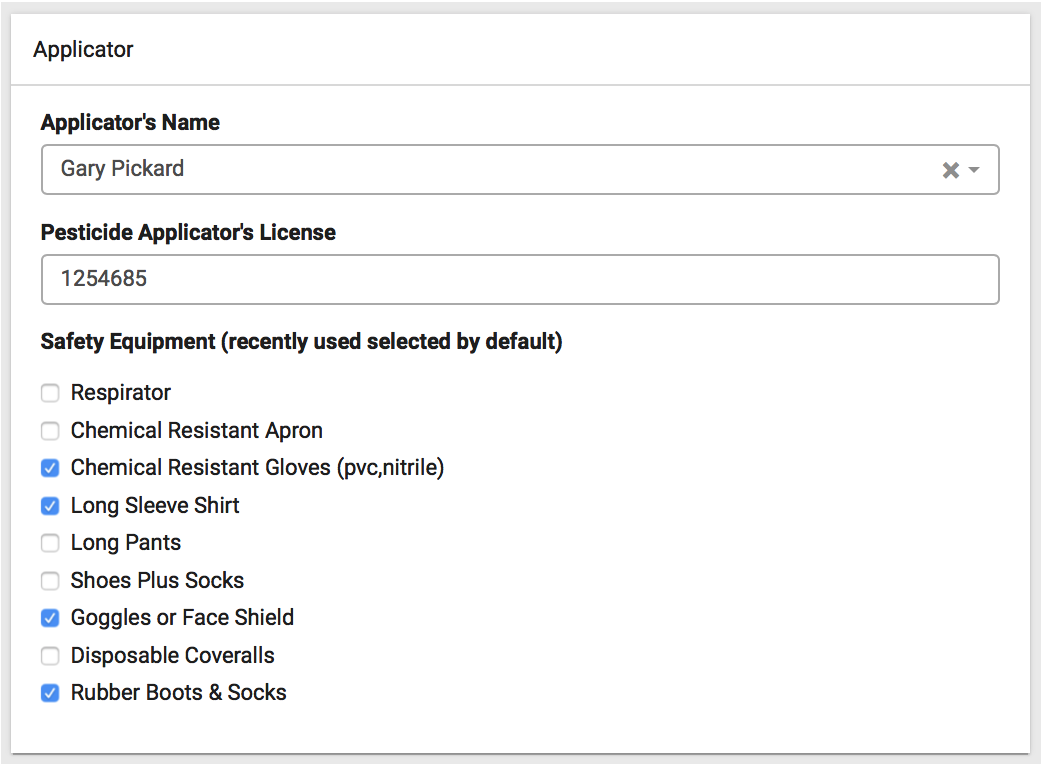

Pesticide exposure incidents cause farm workers more chemical-related injuries and illnesses than any other workforce nationwide. Safety equipment is, obviously, a worker's first line of defense against the dangerous health effects of pesticides. Document what equipment should be used with an associated spray plan, so workers are readily aware of how to best prepare for an application.

When inputting a spray plan in Croptracker, users can select from a list of safety equipment to assign to be worn or used by the applicator. Users can generate work orders displaying this safety information in one click. The work order includes a signature box which the applicator can then sign to confirm they have been made aware of and followed the safety protocol.

Ensure safe re-entry to treated growing areas

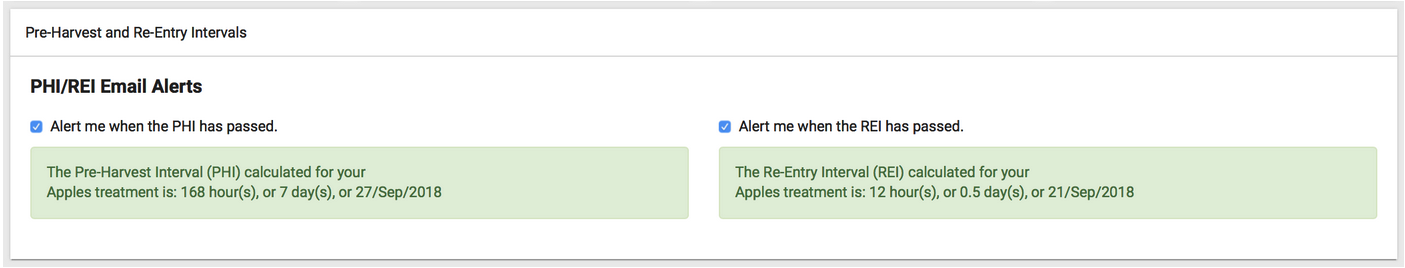

Contact with pesticide residues associated with early re-entry into pesticide treated areas is found to be one of the most common exposure mechanisms.

To help mitigate the threat of early re-entry, Croptracker automatically calculates safe re-entry times for each inputted chemical application based on the specific chemical type's product label. It can then send e-mail alerts to users when the pre-harvest interval (PHI, also known as "waiting period") has passed, and also warns users if they attempt to input a harvest entry in an area that is still unsafe to enter.

Croptracker develops agtech solutions for industry leaders. Designed with fresh market producers and distributors in mind, every tool we create is based on direct industry feedback.

Optimize your harvest season with Croptracker’s customizable solutions: learn more about our Farm Management Software, or book a demonstration to schedule a meeting with our product experts.