In this feature use case blog, we will be highlighting some of the traceability reports in Croptracker. The Mock Recall: Lot Code Report and the Receiving Traceability Report are designed to help users locate the path of inventory through their operations for food safety reporting including real and mock recall scenarios.

In the last several years, traceability requirements for food producers have been formalized and increasing in almost all areas of the world. In North America, both the Canadian Food Inspection Agency and the USA’s Food and Drug Administration have released updated information, resources and deadlines for compliance regarding increased traceability demands on food growers, packers, processors, storage facilities and retailers. Both these traceability systems use similar guidelines and require similar information to be stored and linked to inventory. The FDA guidelines are particularly specific and well defined and we will use them throughout this article.

Food Safety Traceability Definitions:

Traceability Lot Code (TLC):

A unique code assigned to and linked to the inventory that can be traced through all processes and is linked to Key Data Elements about the inventory.

Key Data Elements (KDE):

Information about the inventory that needs to be recorded is linked to it. This information will change slightly depending on what step of the process the inventory is in but generally includes the date the inventory was received or processed and the origin.

Critical Tracking Events (CTE):

A part of the inventory’s process that requires information to be logged and tracked against the inventory. This includes the times the inventory is created, received at new locations, cooled, processed, packed and shipped and received at retail locations.

Traceability Plan:

All food producers and retailers must have a plan to identify and track inventory in the event of a recall. Records of inventory received, packed, processed and shipped must be retained for at least 2 years and the path to find all the information needed for a recall must be documented. Clear process documents for how to find the inventory path need to be maintained and staff need to be trained to find this information quickly. In the event of a recall, this information must be provided to auditors within 24 hours.

Many Croptracker users handle all or part of their traceability plan using Croptracker’s inventory management modules. Harvest, Receiving, Storage, Processing/Packing, and Shipping modules all help to track Key Data Elements (KDE) at various Critical Tracking Events (CTE). Using these modules in combination creates an end-to-end traceability plan. Each CTE and the corresponding Croptracker module are outlined below.

Harvest:

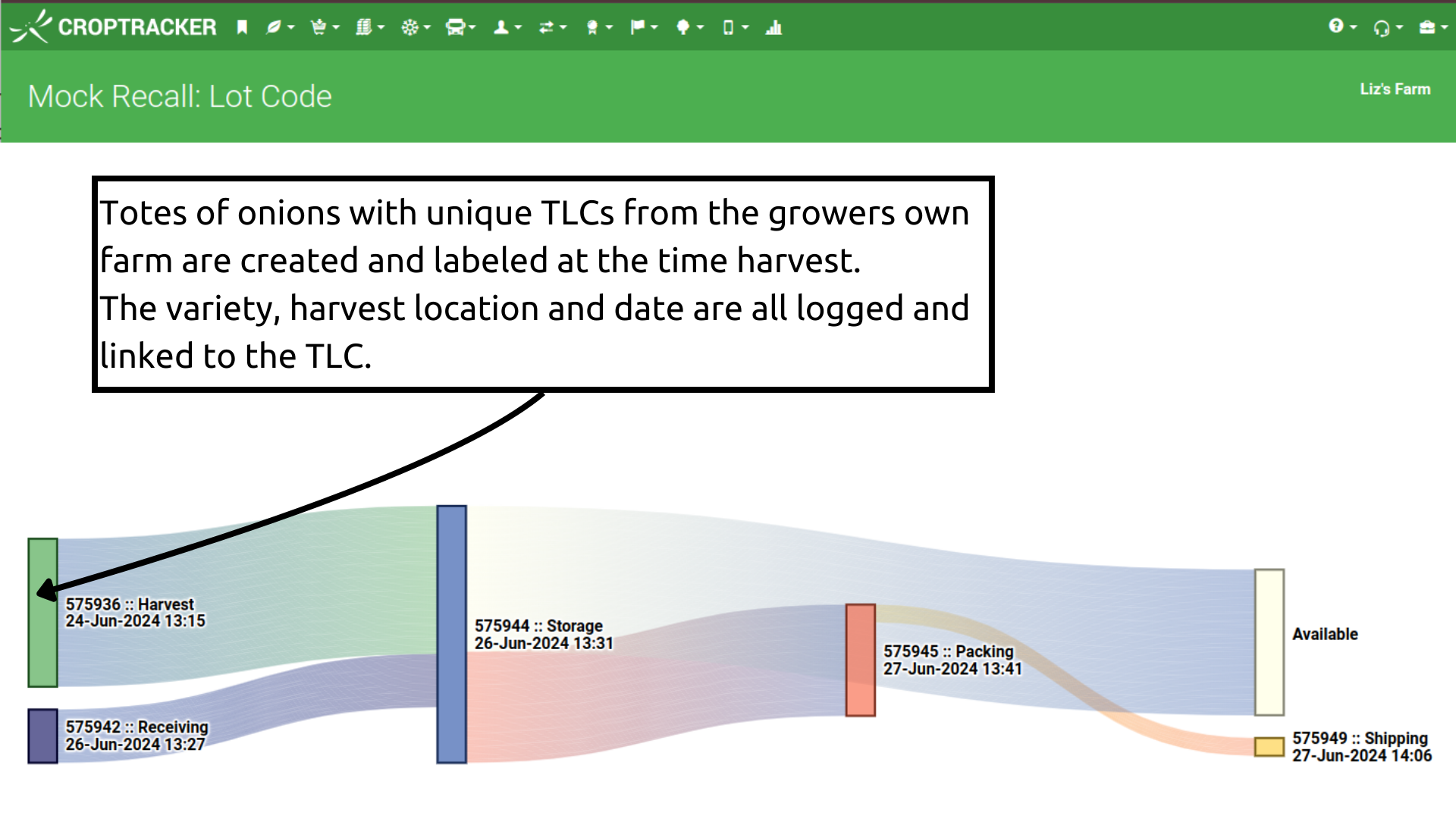

The person or organization harvesting the produce is responsible for creating the initial inventory records including the date it was harvested, the specific location it was harvested from including the ability to reference the location on a map of the farm, and the crop type/variety of the inventory.

All this information can be created and stored in Croptracker using the Farm Map system and the Harvest module. Detailed farm maps including GIS map overlays are available to all Croptacker users and are the organizing structure for linking inventory to its source. Croptracker’s Harvest module supports many workflows to allow users to quickly record what was harvested and where and ensure it is labeled so it can be easily followed through the rest of the process.

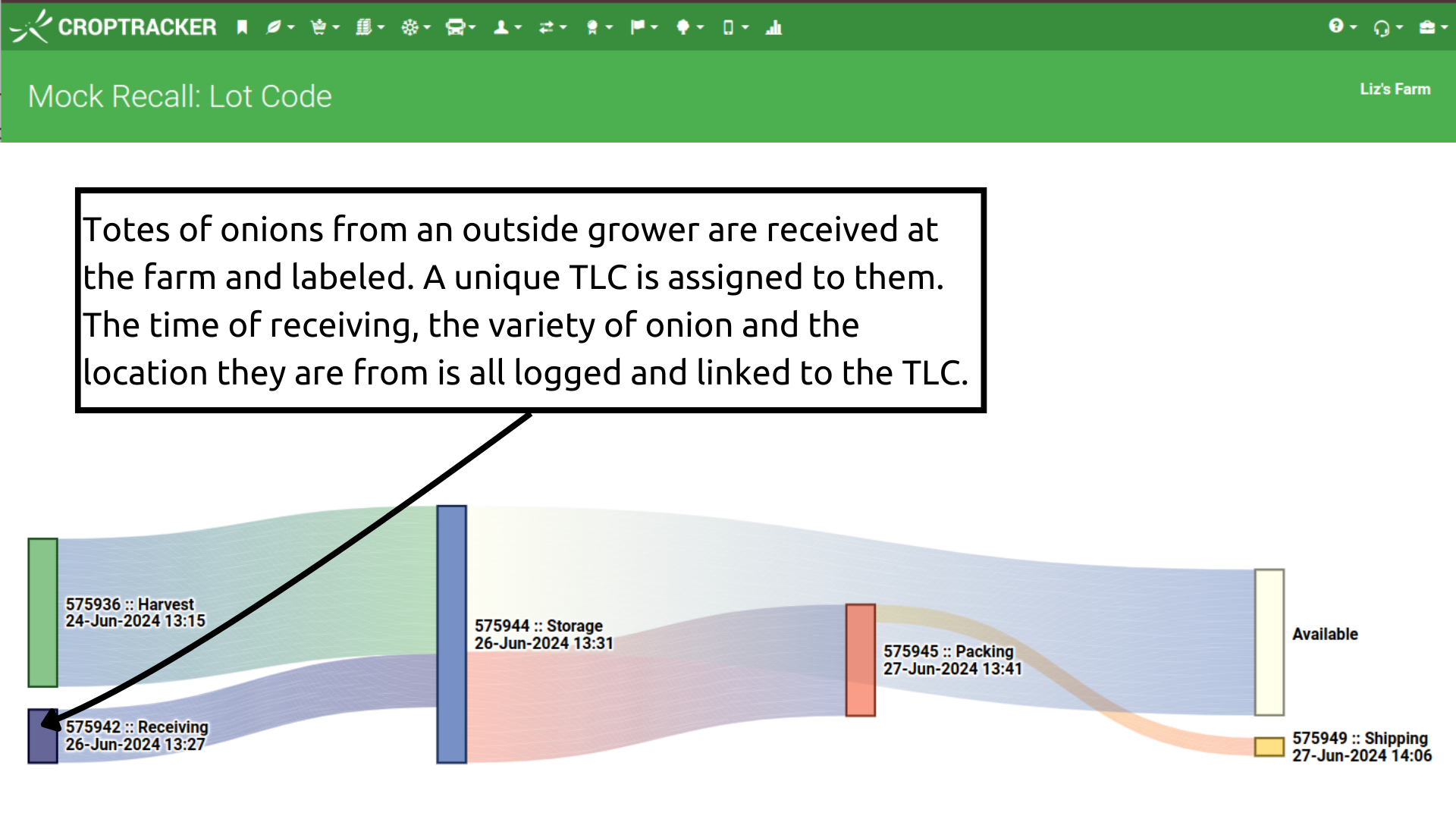

Receiving:

The person or organization taking possession of the harvested inventory is responsible for creating a Traceability Lot Code (TLC). When inventory arrives at a receiving location, the date and origin of the inventory, and the receiving location must be logged and associated with the TLC. The harvester must provide information about the growing location to the receiver when sending inventory to a receiving location.

With Croptracker’s Receiving module, inventory can be assigned a Lot Code and associated with its origin in seconds. New labels can be applied for following inventory through the next steps.

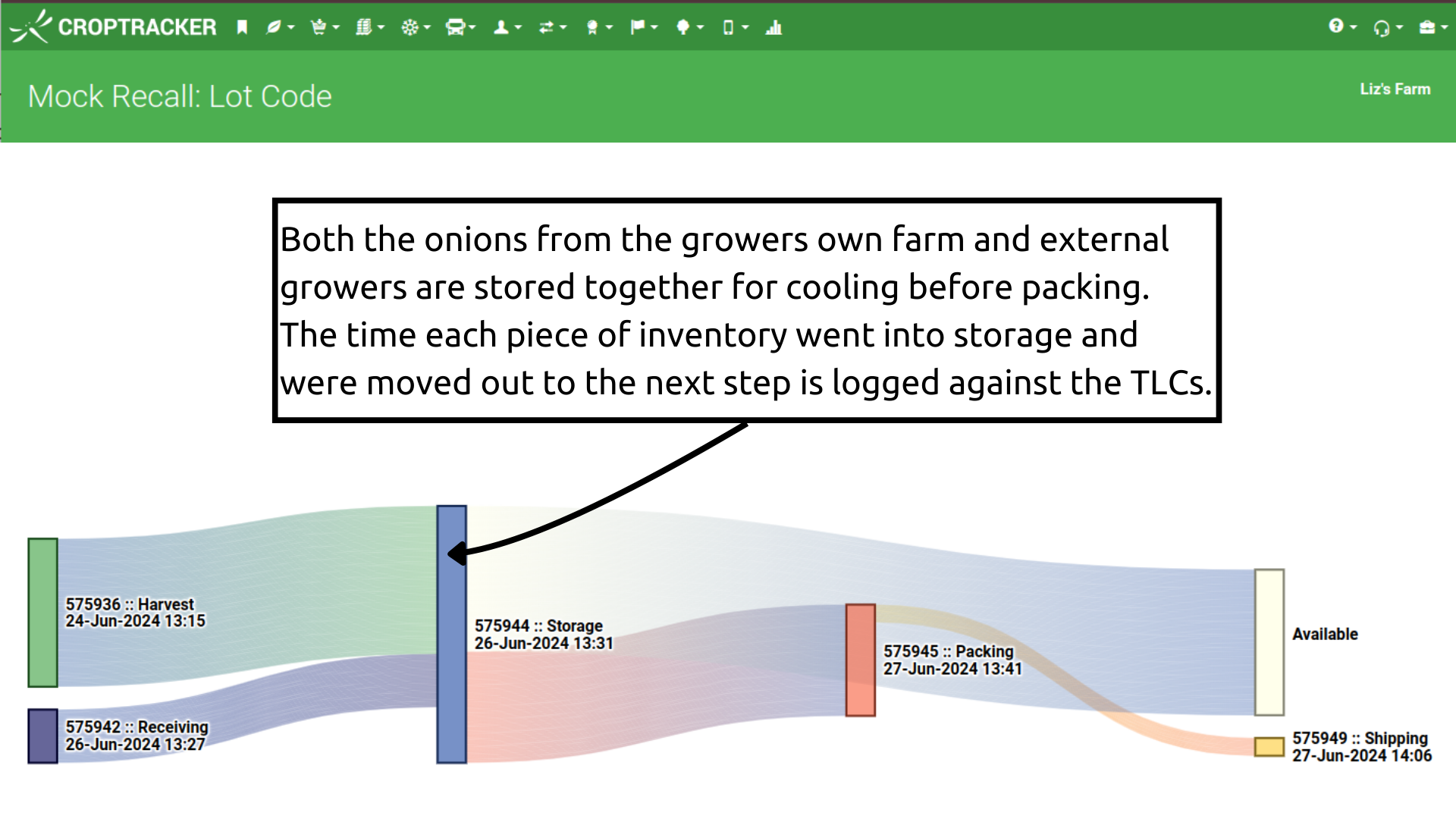

Cooling:

A process of cooling the inventory after harvest before it is packed. (This does not include Controlled Atmosphere storage processes.) When inventory is moved into cooling, the location and description of the location must be kept.

In Croptracker’s storage module, tags can be scanned into rooms for cooling before they are packed or processed. Inventory locations, room details and the length of time in storage can be determined at a glance to prove adequate cooling time.

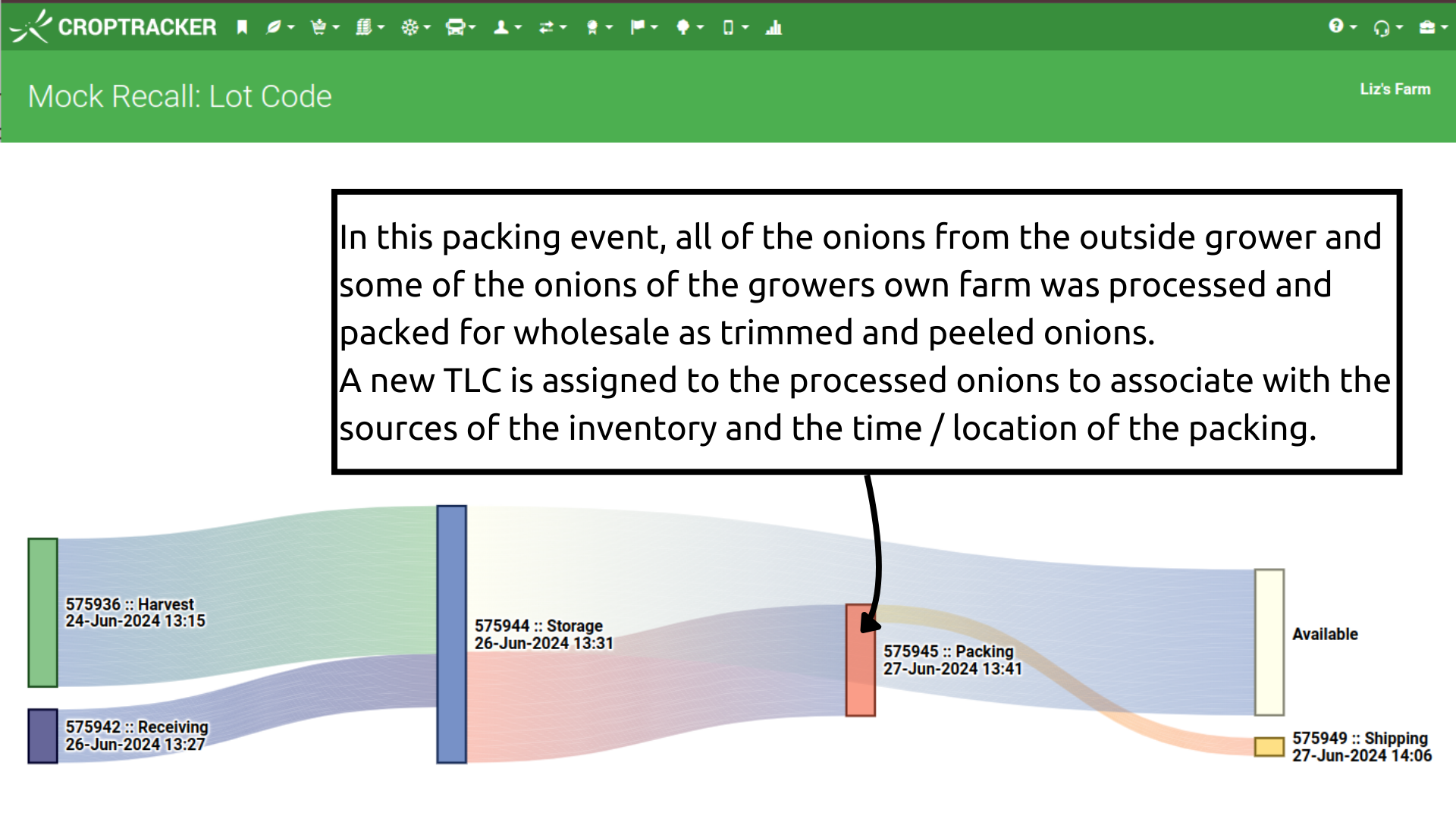

Initial Pack:

The process of first packing after receiving inventory. A new TLC needs to be generated at this point if multiple inventory TLCs are being packed together. The date and location of the pack need to be documented and associated with the new TLC.

Croptracker’s Packing module is used to combine inventory together and record the packed product configuration and amount at the end. The date of the pack, the pack location and the incoming inventory can be easily logged on either the mobile or browser platforms. New product and pallet tags can be printed and applied to directly link new TLCs and for scanning into other processes.

Transformation / Processing:

Any process that transforms the inventory into something else or changes its state, like drying or chopping, must be logged and a new TLC must be issued if the inventory is combined with other inventory. The date and location of the processing must be associated with the new TLC. The Packing module in Croptracker can also be used to record state changes in inventory. If a harvested product is cleaned or chopped or dried and combined with other inventory, it can be assigned a new TLC with updated information about the weight and contents of the processed goods. This inventory can then be packed for retail or shipped to other locations for further processing and packing.

Shipping:

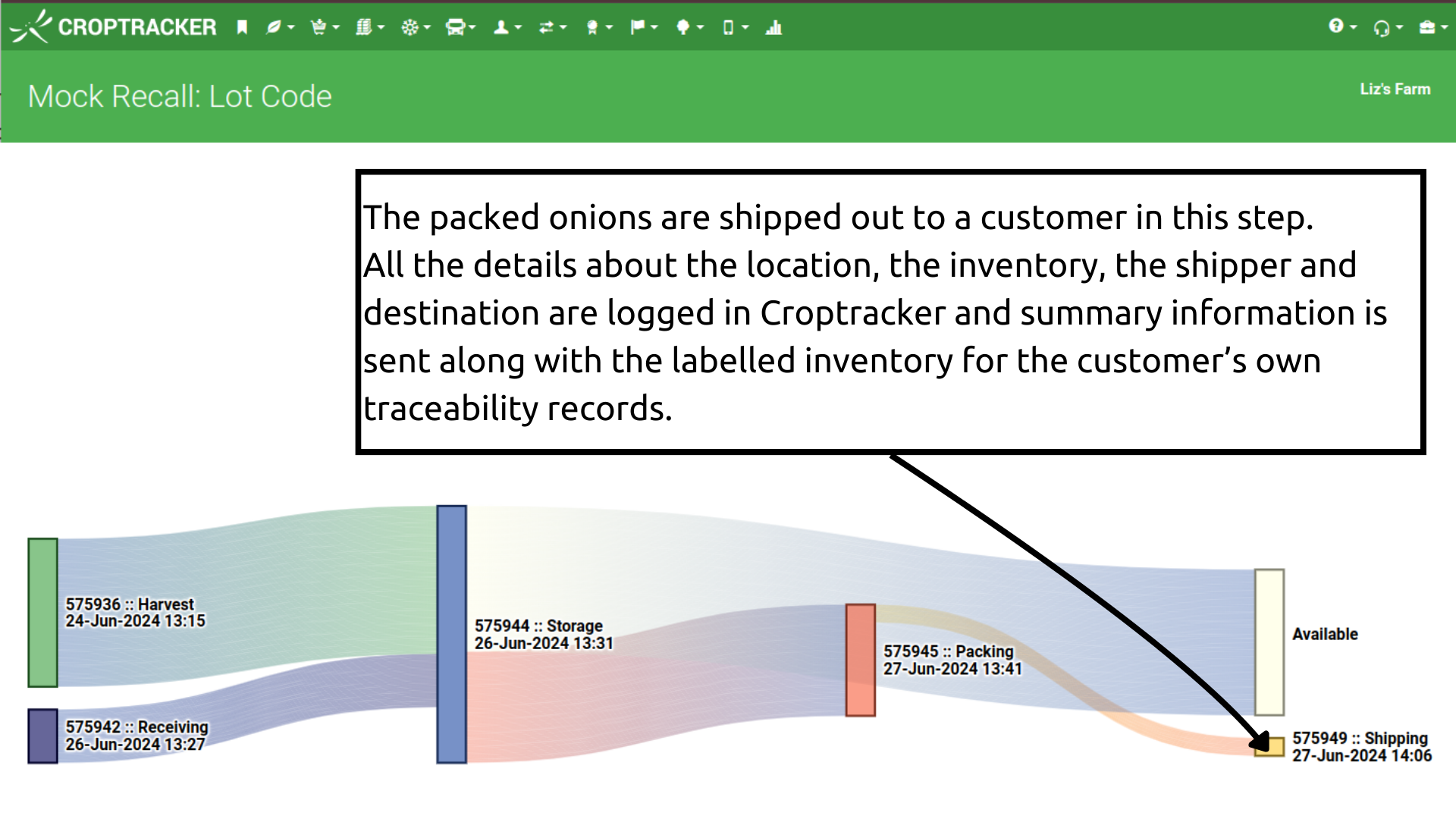

The process of transporting inventory to new locations must be documented including the date, the location it is shipped from and the location it is headed to. If multiple TLCs are shipped at once, all TLCs must be linked to this information.

Recording all the KDEs about shipping in Croptracker can be recorded on the app or the browser in just a few clicks. The date of shipping, the location inventory was shipped from, records of all the inventory being shipped together and the destination can be logged and shipping record summaries can be printed and sent with orders for easy receiving for the customer. The retailer receiving products will have all the information they need for their traceability plan.

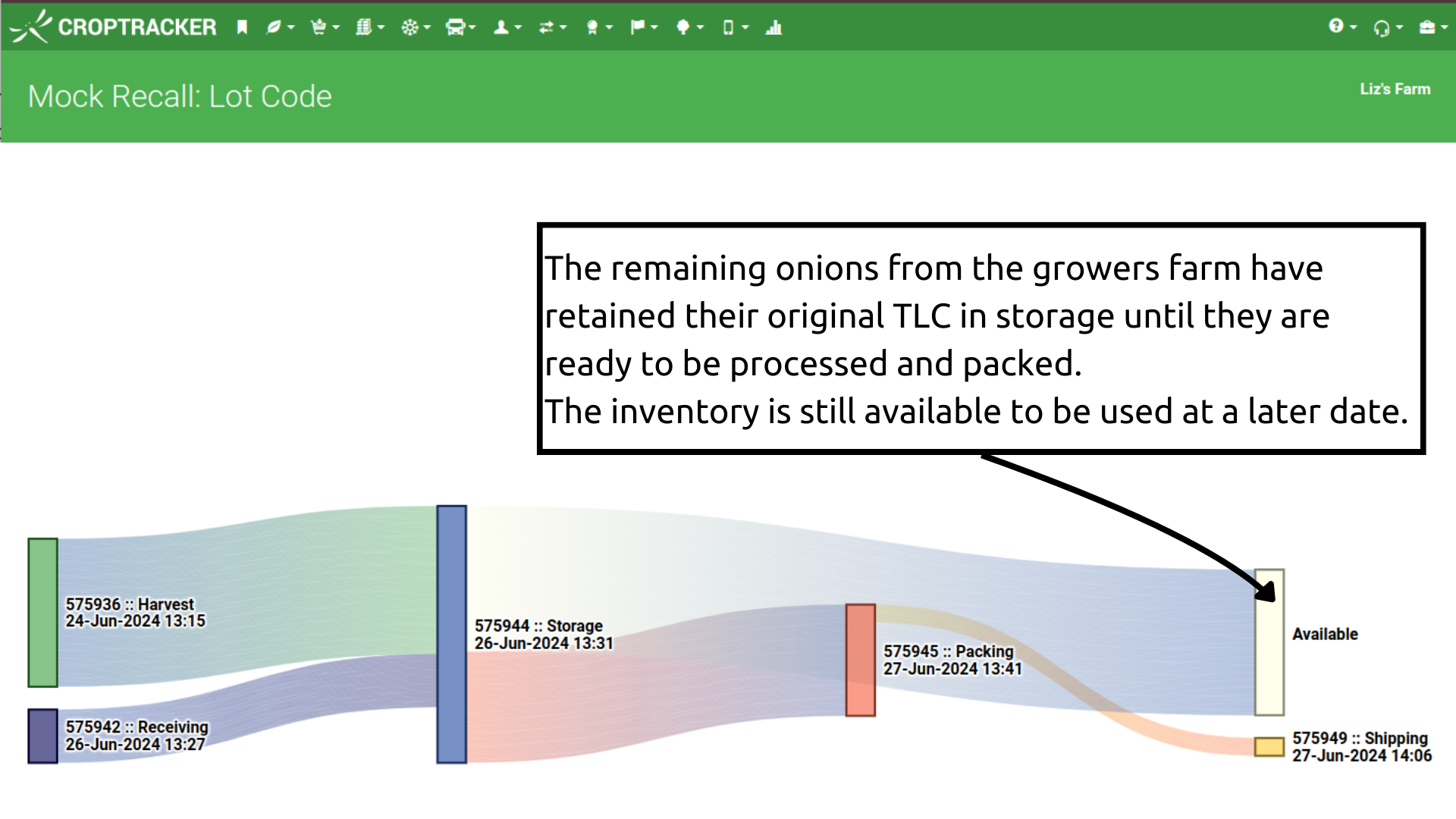

Both the Mock Recall: Lot Code Report and the Receiving Traceability Report are used as visual shortcuts for seeing the whole inventory path. They quickly demonstrate recall readiness and show a Traceability Plan path. Below is an annotated example of a Mock Recall: Lot Report to illustrate the path of onions through harvest, cooling, cutting and packing and shipping to a customer, documenting Key Data Elements at all Critical Tracking Events.

Croptracker's inventory tracking features, including the Mock Recall: Lot Code Report and the Receiving Traceability Report, provide invaluable tools for growers and food producers to meet stringent traceability requirements. By leveraging these features, users can efficiently document and track the path of their inventory through every Critical Tracking Event, from harvest to shipping. This not only ensures compliance with regulatory demands from agencies like the Canadian Food Inspection Agency and the FDA but also enhances food safety by facilitating swift and effective recall actions when necessary. All information is stored securely in one spot and Croptracker’s reports prove the path of inventory movement with the click of a button. Croptracker's modules simplify the process of linking key data elements to Traceability Lot Codes, implementing a comprehensive Traceability Plan seamlessly.